“The energy here is just so good”: A new home for Total Control Pro’s productivity push

Dolores Sanders, co-founder and strategic director of Total Control Pro, explains the reasons for their recent move to Northampton’s Vulcan Works, the company’s journey and the exciting new project driving their growth.

I hadn’t visited at all before that, although I knew it was coming. At the event, I met Gail Haddon, who showed me around and immediately I saw that the energy here is just so good.

We found a room here and we moved in within two weeks. The move was easy, and the team here really made it straightforward, from instant Wi-Fi to helping configure some bespoke bits that we needed. It felt right and it ticked all the boxes.

Overall, the main drive was that we’re a small business and we sit in two camps. Because we’re a tech business, writing code and building interfaces, we need our team to be stimulated by the creative environment – but we’re serving an application solely for the manufacturing industry. This building fits both of those sides of the business perfectly.

We also wanted to move somewhere we could do more customer-facing activities and the meeting rooms at the Vulcan Works provide a good opportunity for that.

The guys we have working flexi time want to come here, for the little coffee places and local businesses. I’ve definitely got more connected to Northampton since we moved into this building.

We found, especially in the run-up to Christmas, the staff finished and popped for a drink somewhere like Maule or V&B which are both brilliant. Pala has just opened in the same area at the top of Derngate which does great pizzas. You’ve got to use these great independent places for them to survive and bringing people into the town centre to work can do that.

We’ve also found that the team at Vulcan Works is committed to what’s going on. It’s always easy to have energy at the very beginning but that energy has been sustained.

Having Barclays Eagle Labs connected in, the Vulcan Creatives initiative, and the NatWest Young Entrepreneurs – does make a difference.

The team here are committed to values that are like the values of our organisation as well. That makes you feel like you’re in a good ship and someone’s steering in the direction you need to go.

All startups worry about cost, which is understandable. The opportunities that come from the peripheral activities just make it easier for businesses as a whole.

When we were moving in, one of our team did some research and found out that back in the 1890s, the engineering company based in what is now the Vulcan Works developed punch card technology for the shoe industry. This meant they could start to stamp leather out of a sheet in what we now know as a normal process. That technology is the basis on which modern printed circuit boards are built.

When you start to find out things like that, it grounds us in the engineering heart of Northampton. Being here, we also get the chance to catch up with other businesses and get inspiration from them, from something like a robotics company to Revolution Radio. This building is really offering those stimulating surroundings.

We are a team of 10 based at the Vulcan Works and working remotely across the world. We’ve moved from being product-focused and getting the product right to being more customer-focused now, getting it out there to more clients. We’re still refining what we have and that will never stop, but we’re at a commercialisation stage now.

Our approach is that we’re committed to building technology for the SME manufacturing environment. There are very good digital technologies designed for companies that have a £ 100 million-plus turnover, but they can be extremely expensive. 96% of UK manufacturing operates on less than a £100million turnover, but a lot of those businesses also need to be on that digital journey.

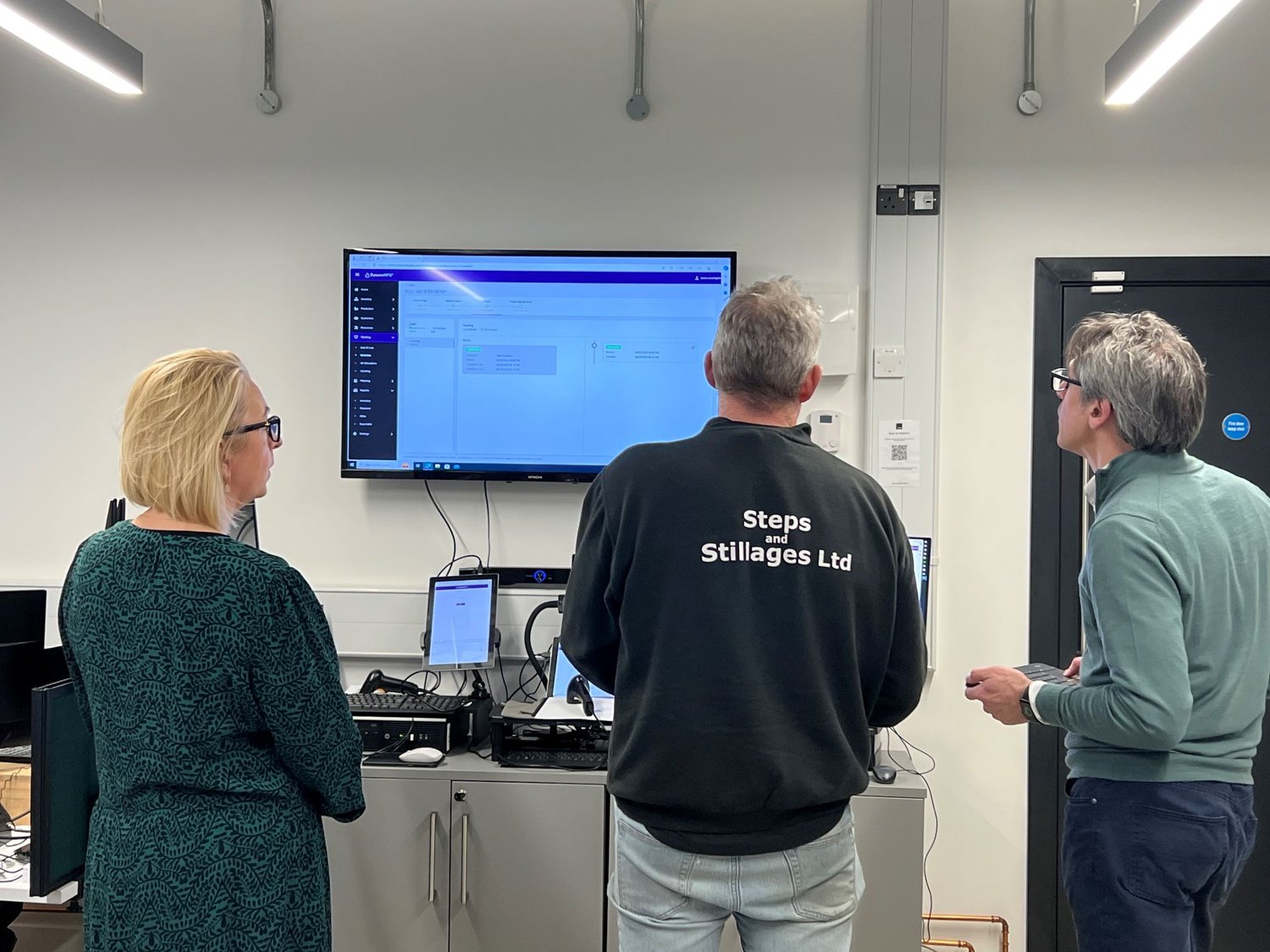

So, we’ve developed a smart manufacturing platform, DynamxMFG, that’s on the cloud, based per user.

This means a small company can get just as much access to the same technology as a larger organisation – it’s just the economies of scale on a user basis.

Taking what we understand about Netflix, for example, but putting it into a manufacturing plant. It’s solely designed for manufacturers – which is different to other products in the market where they’re adapting things to try and serve a manufacturing environment.

A lot of the product development has been funded through Innovate UK projects, so we’ve been very connected to the manufacturer environment and community while building it. And overall, our product gets the right people to the right place at the right time to do the right job. It captures all the necessary data for an organisation’s carbon tracking and if you connect suppliers through our system, it shows you the full digital handshake of a product through up to JCB and Jaguar Land Rover.

I’m really committed to moving people to digital processes. Imagine you’re on the shop floor and you have people carrying out complex welding. They want the simplest possible way of registering what they’re doing and finding out what they need to do next. We found that we save 30 minutes per operator per day because we’re letting them know that without confusion, so they can get on and do their jobs well.

Most manufacturers still stick to paper because of the cost of implementing the digital process, so they’re marking things off on cards. We have a change management process to put in place, to get them engaged with the benefits of that digital process – the work being done is recorded and visible by everyone that needs to know.

We’re also getting more and more young people joining a manufacturing environment and they expect it. We’re bringing gamification onto the shop floor.

Our exciting recent news is that we’ve just got a major project that includes funding for 35 manufacturing companies to provide their data from our system to a central area where it can be analysed by data scientists for feedback, improvements and benchmarking for UK manufacturing.

This is the next step of the Women in Innovation Award that I won for a previous set of industry benchmarking.

Back then we were trying to do it on our own, but now we’ve got a major UKRI project backing it along with other consortium partners, which is really exciting.

As part of that project, we’ll be doing some events here in Northampton that bring some of those clients from across the UK together to share best practices. It’ll be really helpful for manufacturers to share knowledge. They’ve gone, and continue to go, through some really difficult times with supply chain issues and the cost of energy.

Getting together will give them the chance to ask questions of themselves. How am I doing against someone of a similar size employing a similar number of people in terms of output? Could I be utilising something better or saving energy in some way? Could I be improving productivity?

Productivity is a big issue in the UK. We have a problem to solve – just a 1% improvement to SME manufacturing productivity would put £1billion back into the economy on a yearly basis. Just 1% – and we save 30 minutes per operator per day with our product.

If you’ve got 50 people on the shop floor, that’s 10,000 hours. We talk about the fact there’s a skills shortage in manufacturing but let’s actually help people who’ve got the skills do those roles better. Then you start to bring those problems down.